Last Updated APRIL 2024

Manufacturers are spending on capital equipment, but are they protecting their investment?

Industrial manufacturers worldwide share concerns about the challenges affecting the global economy and their businesses, such as pricing, labour, supply chain and energy.

Although manufacturers are navigating near-term economic turbulence, their confidence in the future is unwavering as investing in capital equipment remains a priority.

For example:

In Australia

Private capital expenditure on machinery and equipment to increase by

3.2%

in 2022-23Amounting to

$88.3B

Strong business profit, and increasing capital expenditure from the private sector, are expected to boost private spending on machinery and equipment in 2022-23.1

While the outlook for industrial capital equipment spending is trending positively, opportunities still exist for manufacturers to better protect these high-cost investments.

Protecting your investment

Plant Services’ Machine Maintenance & Reliability Industry Survey results reveal a critical blind spot that currently exists among manufacturers when it comes to protecting their capital equipment investments.

Of the 150 corporate and plant floor professionals from small to large-sized manufacturing companies surveyed,

ONLY

1/3

have the ability to visualise the real-time conditions of critical assets across all sites.2

Additionally, while most manufacturers (83%) utilise Preventive maintenance strategies to help safeguard their capital equipment investments, many rely on Reactive maintenance, the practice of running to assets to failure, within their facility. Very few of respondents rely on condition-based, Predictive maintenance to detect malfunctions and plan maintenance.

When spending on high-cost, productivity-driving equipment, identifying and implementing the right maintenance strategy to support its long-term, useful life is as important as making the right capital investment for the business.

With the right maintenance strategy in place, manufacturers can mitigate major risks to productivity and revenue growth, such as unplanned downtime, long-lead time to acquire replacement parts and expensive, repair-related labour costs.

However, deciding which maintenance strategy aligns with the right purpose for manufacturers is still a widely debated and discussed decision.

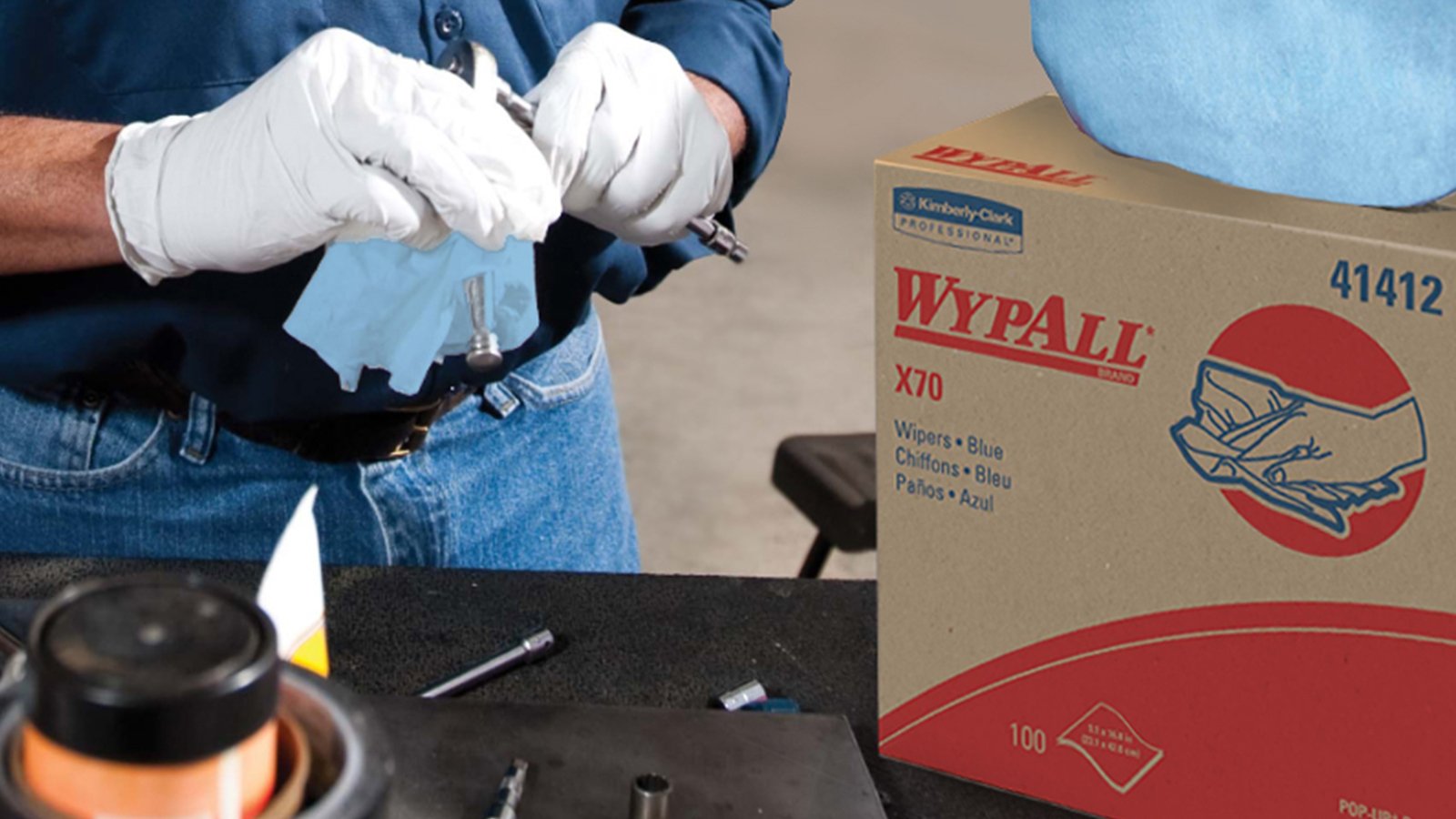

As a global manufacturer and supplier of maintenance-enhancing industrial cleaning wipes, we’ve offered our perspective on the importance of selecting the right industrial manufacturing maintenance strategy in our new eBook: Predictive, Preventive or Reactive Maintenance: Is your strategy aligned with the right purpose?

Download your copy today to learn why utilising the right maintenance strategy is critical to protecting your long-term capital equipment investment.

Download Now

1 Private Capital Expenditure on Machinery & Equipment, https://www.ibisworld.com/au/bed/private-capital-expenditure-on-machinery-equipment/81/

2 Plant Services Report, Machine Health is Business Health, https://info.augury.com/Plant-Services-Report-LP-B.html